Sustainable small-scale brick production

Practical Action

Brick production

The energy question

The theoretical energy requirement to fire bricks has been put by Barriga et al. at 0.85 MJ/kg

of fired brick. A lot more energy is used in practice, as a range of sources illustrate:

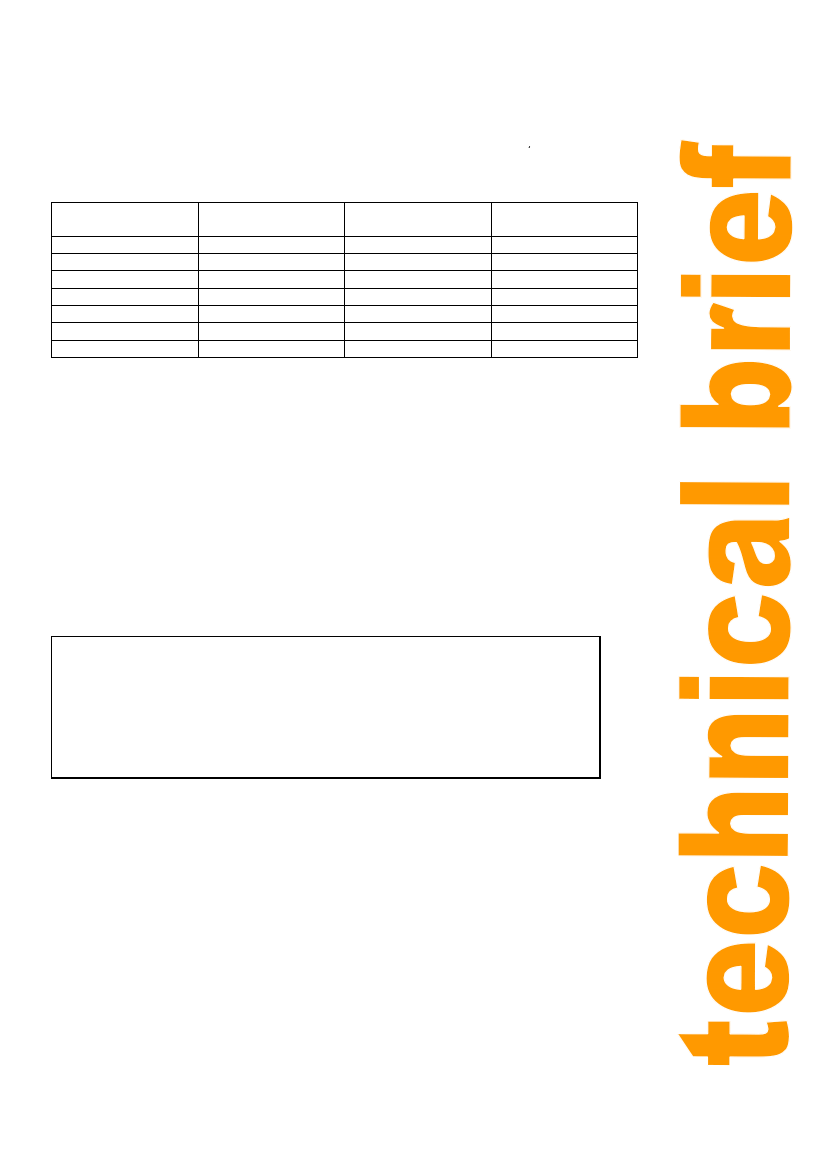

Kiln types

Traditional clamp

Intermediate clamp

Scotch kiln

Vert. Shaft kilin

Bull’s trench kiln

Hoffmann kiln

Tunnel kiln Co

Fuel types

Biomass

Coal, coke

Biomass

Coal…

Coal….

Coal, gas, oil

Oil, gas

Energy use (MJ/kg

fired brick)

3.0 – 8.0

2.0 – 4.5

1.5 - 7.0

0.8 – 1.4

1.1 – 4.0

1.5 – 4.3

1.5 – 2.0

Energy efficiency (%)

10- 28

19 - 42

12 - 59

60 – 100

21 - 77

20 - 56

45 - 56

Information on energy use in brickmaking, though, has largely been collected in a random

fashion, making data such as the above no more than indicative, For example, a report could

state that a certain enterprise uses 0.7 cubic yards of fuelwood to fire 1000 bricks. Without

knowing the type of wood, its moisture content, weight and calorific value, nor the weight or

moisture content of the bricks and the quality of the final product, we do not know much

about energy efficiency.

A standard to compare energy efficiency

When attempting to improve energy efficiency and to share lessons with other researchers or

producers, there is an obvious need to have a more precise method of collecting energy data.

The method described below was evolved by Practical Action and has since been applied in

Peru, Zimbabwe, Sudan and Ecuador.

An important component of this standard method is the specific firing energy; this can be

derived as follows

1) Total energy used (Mj) = mass of fuel (kg) x net calorific value of the fuel

(MJ/kg);

2) Drying energy (MJ) = wet mass of green bricks minus dry mass of green

bricks x energy required to evaporate water (2.591 MJ/kg);

3) Firing energy (MJ) = total energy (MJ) – drying energy (MJ);

4) Mass of fired brick (kg) = average fired mass (kg) taken on a sample of at

least 24 bricks x number of bricks fired;

5) Specific firing energy (MJ/kg) = firing energy (MJ)/mass of fired brick (kg)

Apart from the calorific value, which usually requires laboratory testing, the other data is

relatively easy to collect and calculate. This is not, however, the only piece of information

required to decide whether firing has been efficient or not. First of all, there are observations

to be made with respect to kiln type, location of fuel in the kiln, length of firing, kiln siting,

and climatic conditions. Furthermore, to enable comparison between different sites, we need

to know how easily a soil can be fired. Practical Action has classified soil types as high

temperature. (vitrifying above 1000°C), medium temperature (vitrifying between 950 °C and

1000 °C) and low temperature (vitrifying below 950 °C). This refractoriness of soils can be

tested by firing small cones, with a height of around 70mm and a base of around 15 mm

across, in a suitable test kiln with a controllable firing temperature. The vitrifying temperature

is the one at which the cones bend or slump.

It is also necessary to check how good the fired bricks are, since a kiln can seem efficient, but

produce underfired bricks. Testing certain properties, such as strength or porosity, is

inadequate for that purpose, since they are not only a function of firing. Measuring

temperatures against time in various locations of the kiln is a possibility, though an expensive

3